Application:

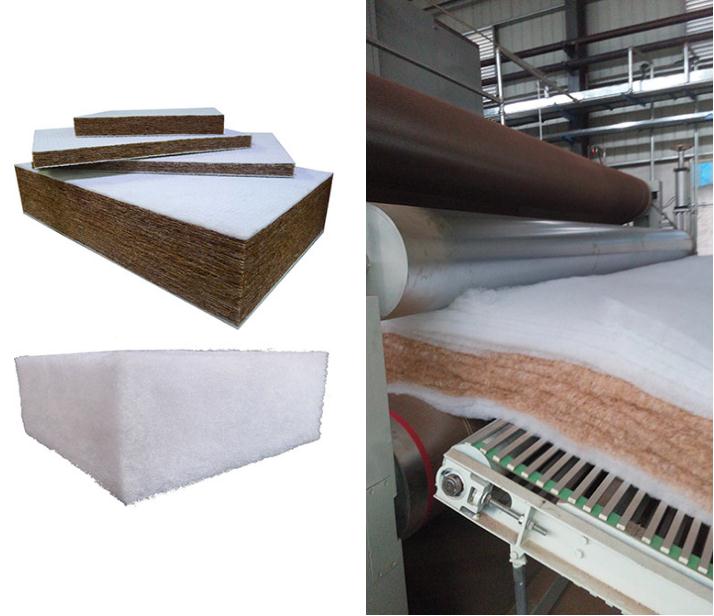

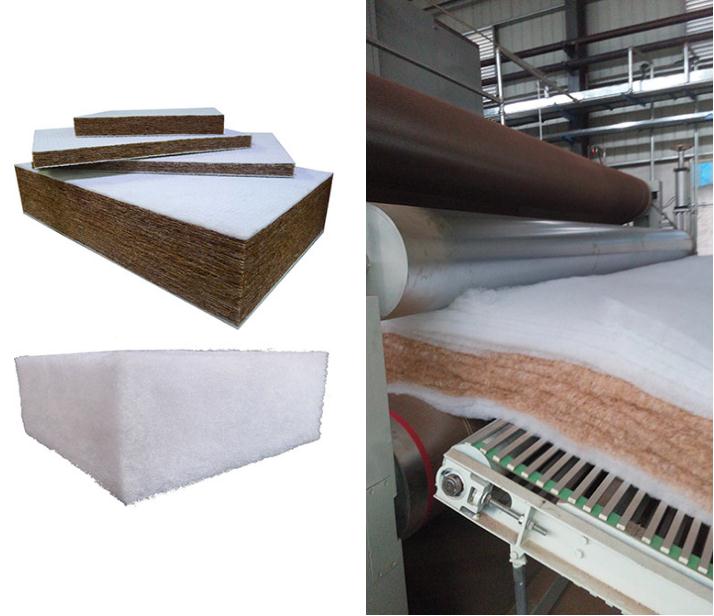

The hard cotton produced by the unit is mainly used for producing:

The new type of chemical fiber coconut palm mattress is mainly made of coconut palm silk and polyester staple fiber. It does not contain glue, formaldehyde and other harmful substances. It is non-toxic, tasteless, fireproof and in line with European environmental protection level. Used for advanced mattress, sofa cushion, etc.

Chemical fiber hard cotton is a substitute for sponge, the main material is polyester staple fiber, non-toxic, tasteless, fireproof, in line with European environmental protection level. Used for advanced mattress, sofa cushion, filter material, sound-absorbing felt, etc.

More than 130 sets of the equipment have been put into production, including (Zongbao) coconut palm Co., Ltd., Kunshan jimeichuan Fiber Technology Co., Ltd., Guangdong boroderkang, Guangdong Nanhai Jiujiang Zhenyuan Donghai cotton factory, Jiangsu Suzhou mowi Suzhou mowi natural fiber material Co., Ltd.

Main Specifications:

Product width: 2700 ~ 4500

Heating temperature: room temperature ~ 220 ° C

Heat source: direct fired natural gas, plus heat transfer oil, heat exchange, plus hot air

Output: 30 ~ 35t per day

Heat consumption: 200000 ~ 400000 kcal

Product weight: 100-6000 g / m2

Product thickness: 10 mm ~ 200 mm

Line speed: 2m ~ 12m / min

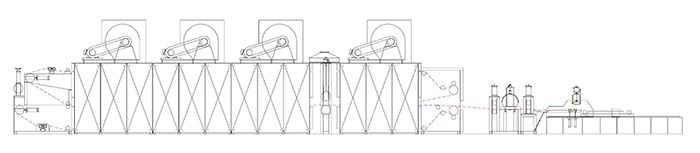

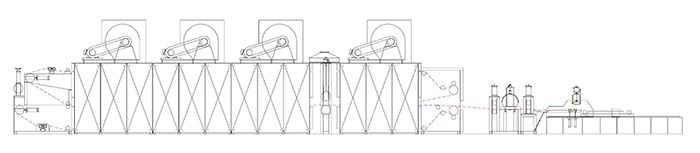

Structural Features:

① The drying room adopts double Teflon mesh belt, and the upper air trough and mesh belt rise and fall synchronously.

② Up blowing and down sucking, down blowing and up sucking pressure penetrating heating.

③ The wind pressure is adjusted by frequency conversion, and the hot air is convective.

④ High thermal efficiency, uniform heating, stable product (thickness, hardness, setting).

⑤ The cutting adopts the moving flat cutting, and the moving platform keeps the linear speed of the drying room synchronized during the cutting, so as to maintain the average speed of the drying room, and the cutting accuracy is ± 1 mm.

⑥ The temperature, speed, wind pressure, product thickness and cutting length of each section in the drying room are all controlled by the automatic human-machine interface.

Production Process:

Hot Drying Room → Cold Press Setting Machine → Cooling Setting Drying Room → Roller → Slitting Longitudinal Cutting → Roller → Moving Platform Flying Knife Cutting.